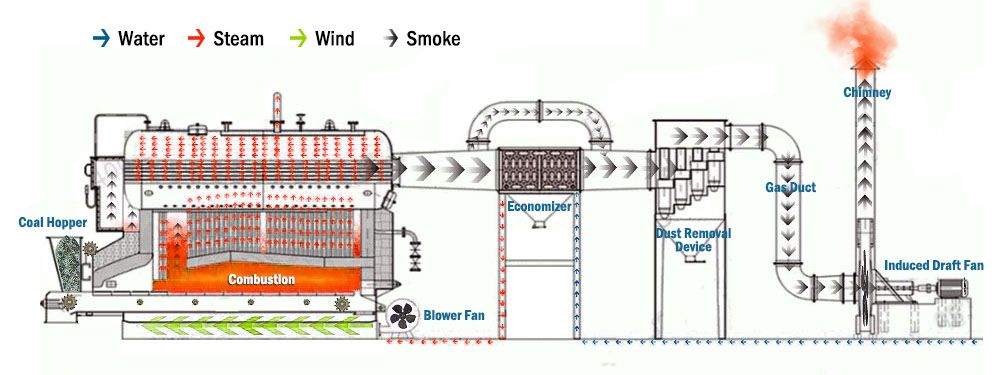

DZL series chain grate biomass wood steam boiler adopts a horizontal three-pass water-fire tube hybrid structure, that is, threaded smoke tubes are arranged in the drum, and the thermal efficiency is improved through multiple heat exchanges. This design can effectively reduce thermal stress and enhance the safety and service life of the boiler. In addition, the horizontal chain steam boiler also adopts a wavy furnace tube and a fully wet-back structure, further enhancing its heat transfer efficiency and stability. Horizontal chain steam boilers are characterized by their compact structure, stable operation, energy conservation and environmental protection. Its automatic control system can achieve precise combustion control and safety protection, ensuring the safe operation of the boiler.

Main Features

1. The adoption of heat transfer threaded smoke tubes has achieved an enhanced heat transfer effect, featuring rapid temperature and pressure increase in the boiler and improving its thermal efficiency.

2. Compact structure, compared with boilers of the same type, it has a smaller external dimension, saving infrastructure investment in the boiler room.

3. Stable operation, convenient adjustment and sufficient output. It has a certain load capacity.

4. The use of threaded flue tubes to enhance heat transfer improves the heat transfer coefficient and thermal efficiency. Due to the disturbance effect of flue gas inside the tubes, ash is less likely to accumulate inside the tubes, thus achieving a self-cleaning function.

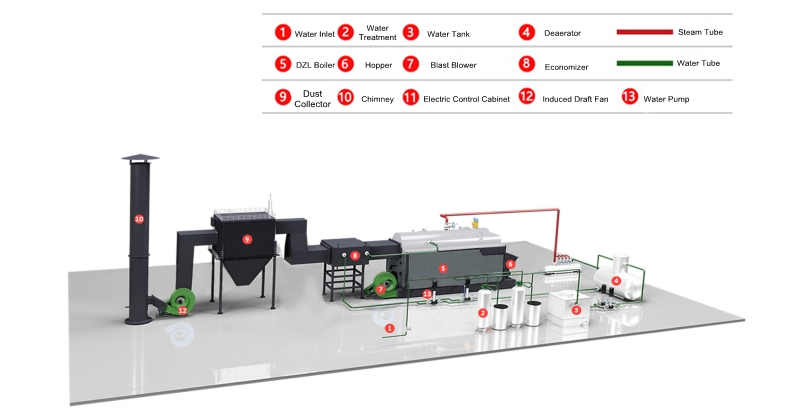

Boiler Process Flow Chart

The fuel burning at the furnace through, the exhaust gas flow from the boiler barrel bottom to the smoke window outlet on the Eight character wall, then enter convection bank at the both wings, next enter the thread smoke tube through the front smoke box, pass by economizer, dust remover, and induced draft fan, finally discharged to the atmosphere by chimney.

Available Fuel

DZH series manual biomass wood steam boiler is suitable for coal and various biomass fuels, such as charcoal, biomass pellets, wood chips, sawdust, wood waste, wood residues, wood cuttings, wood strips, rice husks, rice stalks, rice straw, corn cobs, corn stalks, rice husks, agricultural waste, etc.

Technical Parameters

| Model | Rated Evaporation Capacity | Working

Pressure |

Rated Steam

Temperature |

Thremal

Efficiency |

Fuel

Consumption |

Weight |

| (t/h) | (MPa) | (℃) | (%) | (kg/h) | (ton) | |

| DZL1 | 1 | 1.0/1.25/1.6 | 184/194/204 | >80 | 128 | 17 |

| DZL2 | 2 | 1.0/1.25/1.6 | 184/194/204 | >80 | 258 | 23 |

| DZL4 | 4 | 1.0/1.25/1.6 | 184/194/204 | >80 | 510 | 25 |

| DZL6 | 6 | 1.0/1.25/1.6 | 184/194/204 | >80 | 720 | 40 |

| DZL10 | 10 | 1.0/1.25/1.6 | 184/194/204 | >80 | 1500 | 53 |

| Note: Parameter is for reference only, if any changes should follow the actual drawing. | ||||||

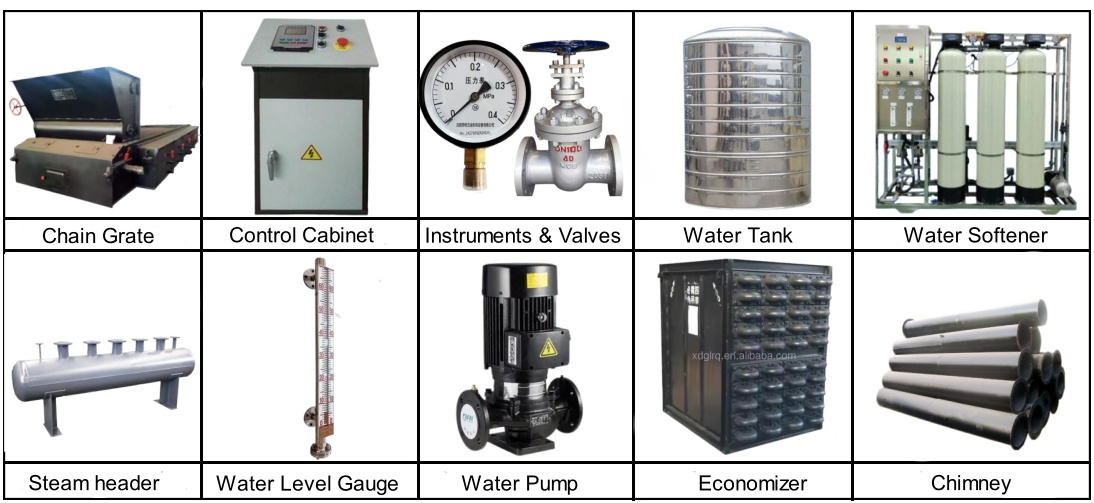

Accessories

DZL series chain grate biomass wood steam boilers include the boiler body, chain grate, instrument valves, steam header, chimney, air duct, economizer, water pump, induced draft fan, blower, etc.