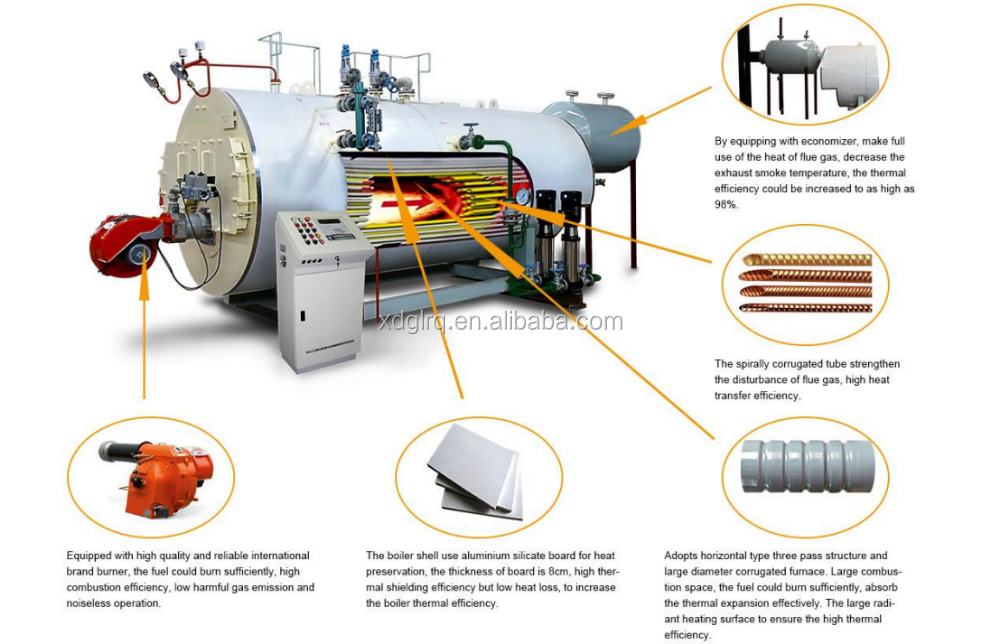

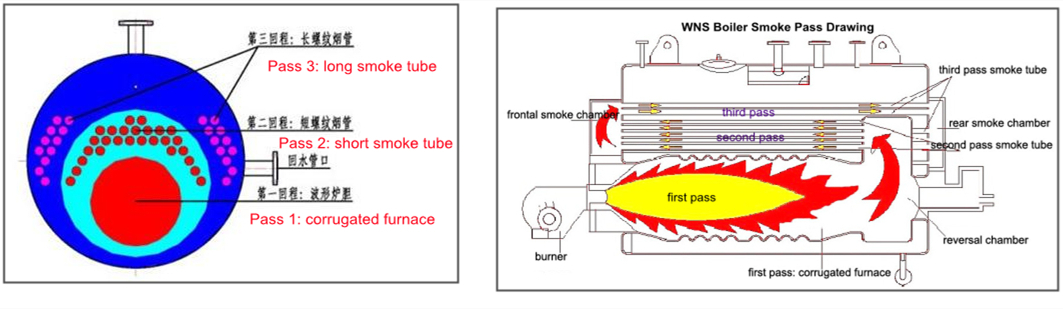

WNS series fire tube gas oil steam boilers are horizontal three pass fire tube steam boilers. The wet-back structure of the offset furnace tube is adopted. The high-temperature flue gas enters the third return flue pipe from the front flue box and is then discharged into the atmosphere through the chimney from the rear flue chamber. The boiler is equipped with a movable rear smoke box cover, which makes the maintenance of the boiler convenient. The boiler is equipped with an industrial burner with excellent technical performance, adopting advanced technologies such as automatic proportional regulation of combustion, programmed start and stop, and fully automatic operation. It also features automatic protection functions such as automatic temperature control and flameout. This type of boiler features a compact structure, safety and reliability, simple operation, quick installation, low pollution, low noise, high efficiency.

Main Feature

1.The control system adopts an intelligent LCD control system, which operates fully automatically. It features automatic water replenishment, automatic temperature setting, combustion start and stop, cycle control, and automatic fault detection, etc. It is easy to operate and safe to use.

2. It is equipped with an imported burner as an option, which ensures complete combustion, no smoke, no dust or noise, and has a good environmental protection effect.

3. The adoption of threaded smoke tubes enhances the heat transfer effect and improves the thermal efficiency of the boiler.

4. The furnace body structure is reasonable, with a large heating area, high thermal efficiency, sufficient water supply, small floor space, compact and beautiful appearance.

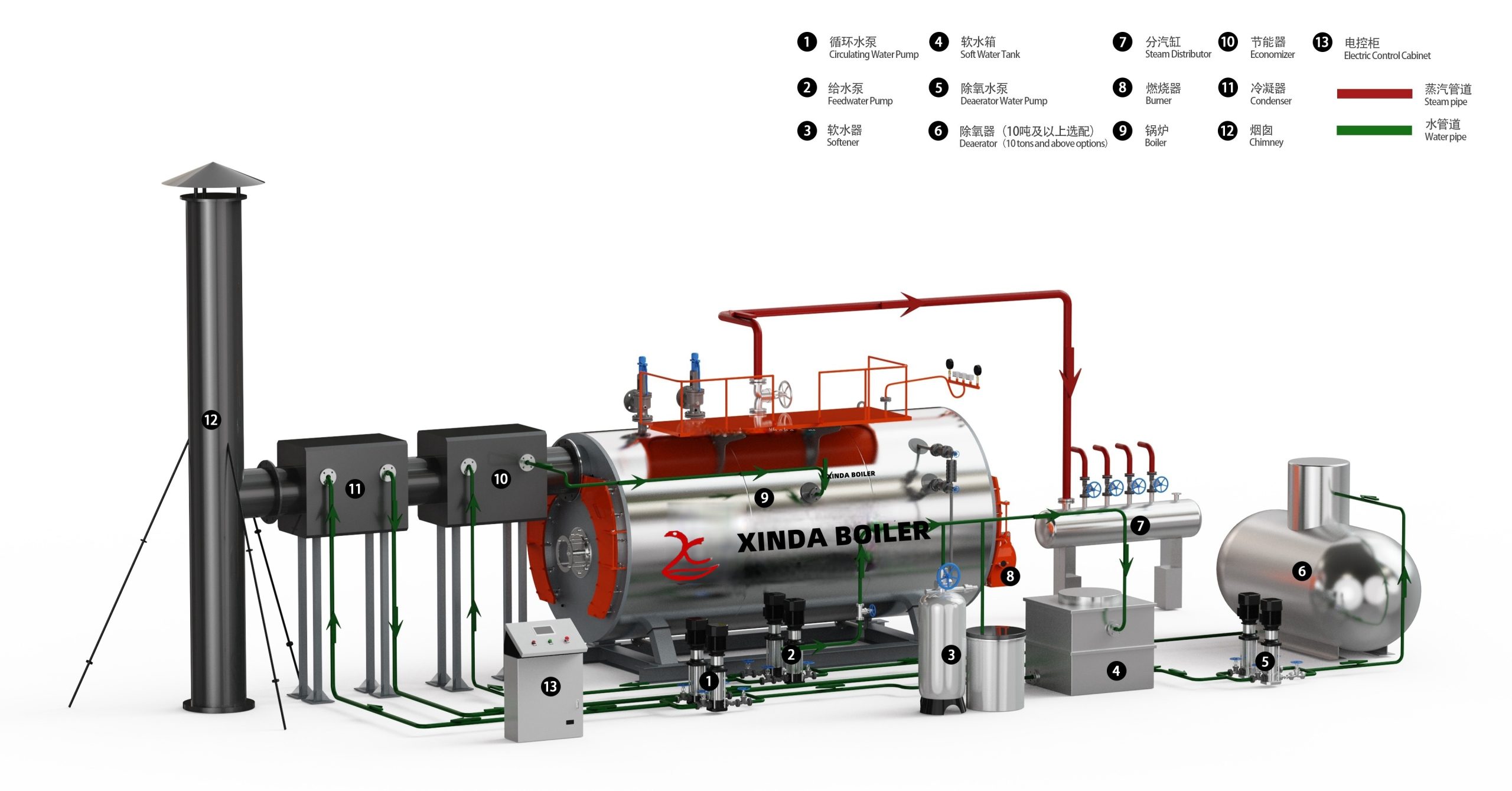

Boiler Process Flow Chart

The figure shows a schematic diagram of the structure of the WNS series gas horizontal three-pass boiler, from which the structure and process of the boiler can be clearly observed:

First pass : The high-temperature flue gas enters the first pass from the furnace, flows through the convective tube bundle, transfers heat to the feed water, and the water generates steam.

Second pass : The flue gas enters the second pass, flows through the superheater, and heats the steam to a superheated state.

Third pass : The flue gas enters the third pass, flows through the economizer, recovers the heat in the flue gas and reduces the flue gas temperature.

Technical Parameters

| Model | Rated Steam

Capacity(t/h) |

Rated Steam

Pressure(Mpa) |

Rated Steam

temperature(℃) |

Fuel Consumption | Boiler Size (m) | Weight (t) | |

| Light Diesel

(Kg/h) |

Gas (Nm³/h) |

||||||

| WNS1 | 1 | 0.7/1.0/1.25/1.6 | 170/184/194/204/226 | 83 | 39 | 3.6×2.0×2.0 | 4 |

| WNS2 | 2 | 0.7/1.0/1.25/1.6 | 170/184/194/204/226 | 129 | 79 | 4.8×2.5×2.46 | 8 |

| WNS4 | 4 | 0.7/1.0/1.25/1.6 | 170/184/194/204/226 | 259 | 314 | 5.8×2.85×2.8 | 13 |

| WNS6 | 6 | 0.7/1.0/1.25/1.6 | 170/184/194/204/226 | 388 | 470 | 7.25×3.1×3.15 | 19 |

| WN8 | 8 | 0.7/1.0/1.25/1.6 | 170/184/194/204/226 | 518 | 629 | 7.45×3.26×3.2 | 22.6 |

| WNS10 | 10 | 0.7/1.0/1.25/1.6 | 170/184/194/204/226 | 647 | 789 | 8.7×3.7×3.5 | 34 |

| WNS20 | 20 | 0.7/1.0/1.25/1.6 | 170/184/194/204/226 | 1200 | 1400 | 10×3.6×4.0 | 45 |

| Note: Parameter is for reference only, if any changes should follow the actual drawing. | |||||||

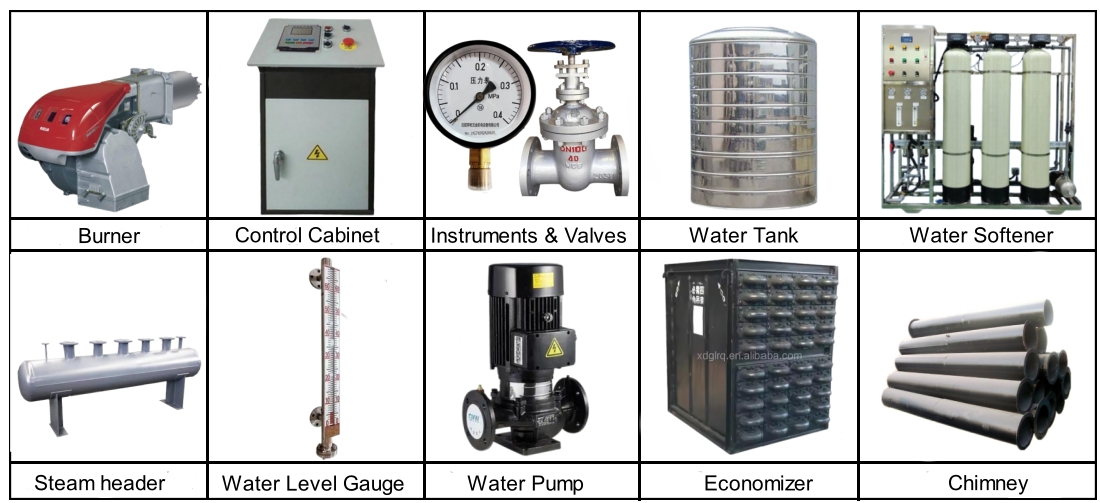

Accessories

WNS series fire tube gas oil steam boilers include the boiler body, burner, instrument valves, steam header, chimney, air duct, economizer, water pump, induced draft fan, blower, etc.

Xinda boiler

Xinda boiler