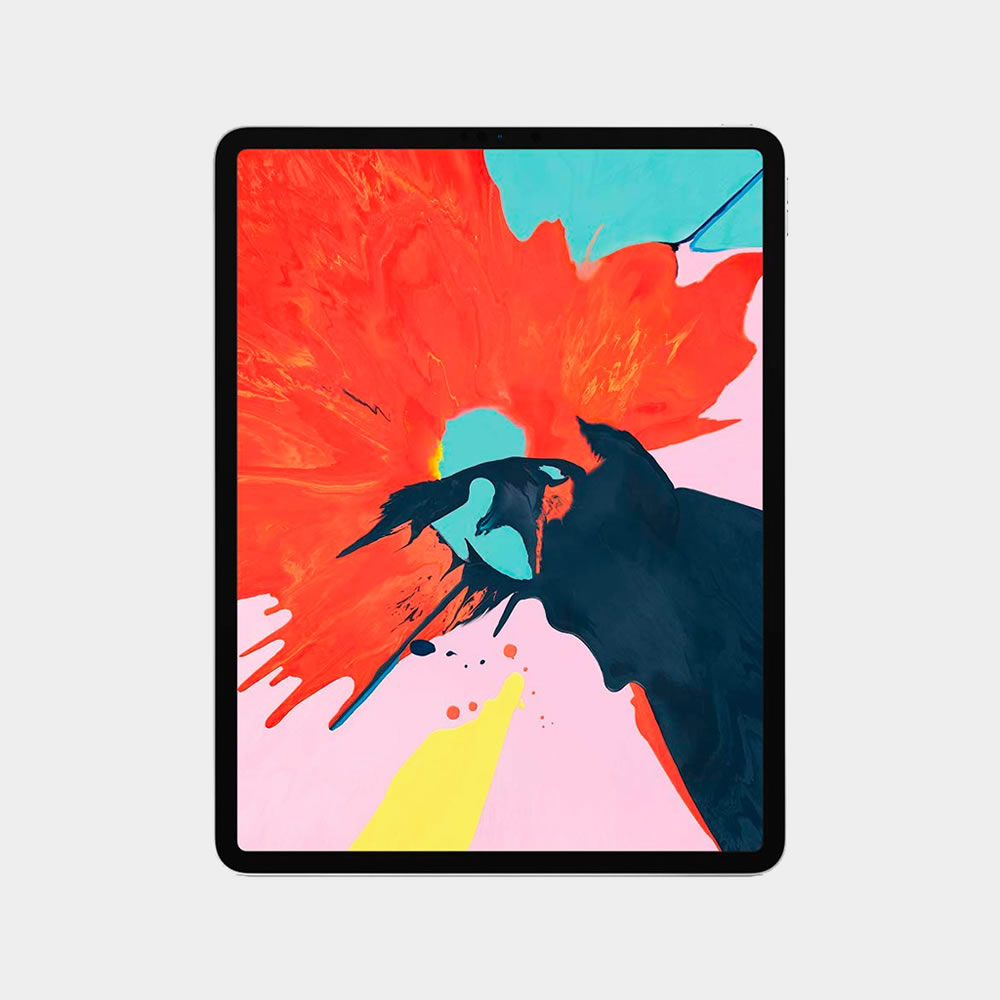

The iPad Pro from Apple, updated from the same one you know and love, steps up from its previous 10.5″ design and ditches the Home button for a display that’s more screen and less bezel. Built with the same Liquid Retina technology found on the iPhone XR, the iPad Pro’s 11″ display features a 2388 x 1668 resolution, ProMotion technology, wide color and True Tone support, as well as a 600 cd/m2 brightness rating. Performance-wise, Apple has replaced the A10X processor with the A12X Bionic chip. This multi-core processor handles all the computational and graphical processing needed for complicated tasks. In addition, it’s paired with a Neural Engine chip for advanced machine learning. With the removal of the Home button which also functioned as the fingerprint sensor, the iPad Pro has opted for Face ID via its front-facing 7MP TrueDepth camera. Lastly, Apple has opted for a USB Type-C connector rather than its traditional Lightning connector for additional features and broader compatibility with other devices.

This iPad comes preloaded with iOS. Please check your device settings for the latest available update.

iPad-Pro

Edge-to-Edge Liquid Retina Display

The Liquid Retina display in the iPad Pro features wide color support, True Tone, and an anti-reflective coating for a natural, accurate viewing experience both indoors and out. It also supports ProMotion technology, which automatically adjusts the display’s refresh rate, up to 120Hz, for smooth and responsive scrolling.

A12X Bionic Chip

The Apple A12X Bionic chip, built on 7nm technology, consists of an 8-core CPU and a 7-core GPU. This chip is designed to tackle complex tasks such as editing photos, creating 3D models, and more. Additionally, a Neural Engine chip works alongside the A12X for advanced machine learning from photography to AR.

Face ID & Cameras

Face ID & Cameras

With the removal of the home button, the iPad Pro now utilizes its 7MP front-facing TrueDepth camera with Face ID for security and unlocking your device. It works in any position and enables you to use Apple Pay in apps as well as Animoji and Memoji in chats. At the rear is a 12MP camera, which supports 4K video, document scanning, and AR experiences.

Apple Accessories

Built with over 100 magnets, the iPad Pro seamlessly connects to additional accessories. The Apple pencil can magnetically attach to the side of the iPad Pro for simultaneous pairing and charging. On the other hand, the magnets firmly secure the Smart Folio Keyboard in place and detach easily for alternate viewing modes.

USB Type-C

The USB Type-C connector has replaced the Lightning connector as a one-cable solution for a wide variety of connectivity options. It supports USB 3.1 Gen 2 speeds for up to 10 Gb/s file transfers, an external 5K resolution display, and even other devices for sharing power.

Battery Life

Built with a 29.37 W lithium-polymer battery, the iPad Pro is rated to last for up to 10 hours while surfing the web on Wi-Fi, watching videos, or listening or music. Models utilizing cellular network data for these services will have around a nine hour battery life instead.

Apple sales are fleeting, but we’ve seen a bundle of great iPad deals lately in the wake of the release of the new iPad Mini and iPad Air. Most of these discounts have been for the standard 2018 iPad (which is our recommended tablet for most people), but the iPad Pro is still Apple’s best tablet by a mile. If you’ve been thinking about grabbing one, now’s a good time, as the third-generation Pro just got a nice discount on Amazon for both the 11-inch and 12.9-inch models.

Apple sales are fleeting, but we’ve seen a bundle of great iPad deals lately in the wake of the release of the new iPad Mini and iPad Air. Most of these discounts have been for the standard 2018 iPad (which is our recommended tablet for most people), but the iPad Pro is still Apple’s best tablet by a mile. If you’ve been thinking about grabbing one, now’s a good time, as the third-generation Pro just got a nice discount on Amazon for both the 11-inch and 12.9-inch models.

The iPad Pro is more than just Apple’s greatest tablet, it’s also arguably the finest tablet ever made. Our team gave the Pro a glowing review due to its sleek design, great performance, and most of all, its versatility. This tablet can operate much like a laptop when paired with a Bluetooth keyboard, including Apple’s own Smart Keyboard Folio (although you’ve got plenty of other options), and it’s also compatible with stylus pens like the Apple Pencil.

As anyone who is familiar with Apple hardware knows, display technology is one area where iOS devices really shine, and both the 11- and 12.9-inch models pack absolutely gorgeous Liquid Retina touchscreens. These panels boast high-definition resolutions of 2,388 × 1,668 (11-inch) and 2,732 × 2,048 (12.9-inch) as well as impressive 120GHz refresh rates for super-smooth video playback. Compared to the second-gen 10.5-inch iPad Pro, the 11-inch 2018 model also features slimmed-down bezels which offer a sleeker design and more screen real estate while remaining the same overall size as its predecessor.